Plus, options to specify some instructions for the 3D printer is also provided by it like layer height, vertical shells, seam position, speed for print moves, speed of non-print moves, material type, and more. In this software, you also get tools to view a 3D model from all directions such as top view, bottom view, right side view, rotate plane, etc.

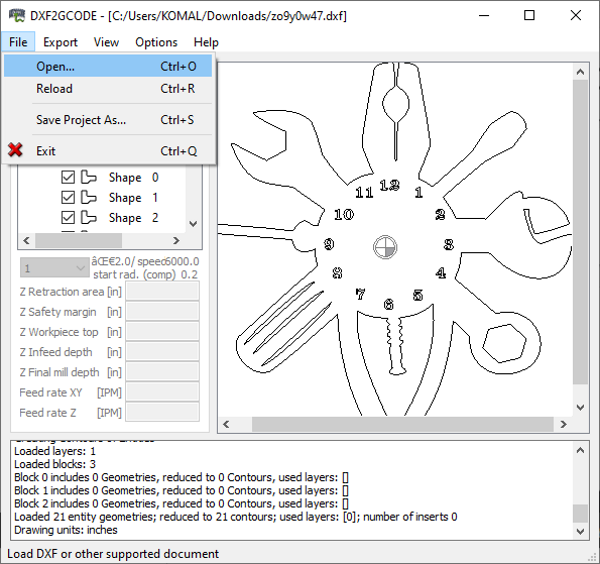

DXF FILE TO GCODE CONVERTER SOFTWARE

It is a dedicated 3D printing software through which you can generate the G-code of a 3D model present in an STL file. Follow the below steps to convert STL to G-code. Bugiardino vaccino covid aifaīefore starting the conversion process, you can use its Settings tab to specify printing material, print core dimensions, layer height, infill percentage, etc. After loading a 3D model, you can use its inbuilt viewing tools to view an input model from different directions. Through this software, you can easily generate a G-code using the 3D design contained in an STL file. It is a feature-rich converter that offers all the essential tools to successfully perform STL to G-code conversion.

If you go to the Options window of this software, then you can also specify and adjust some printer parameters such as printer model, coordinates of starting position, dimensions of the model, g-code header, g-code footer, etc. This software also offers model viewing tools like rotate, scale, move, etc. However, before starting the conversion, you can also make some modifications to input 3D model using its Split disjoint surfaces of the modelBisect cut a model into two partsand Drop align and place an object over the bed surface tools. Go through the list to know more about these converters. To further help you out, I have also included the complete STL to G-code conversion steps in the description of each software. In general, these are quite featured software using which you can easily generate G-code of an STL model. After that, you can specify various printing parameters to generate G-code according to your specifications. Through some software, you can also make some changes to the model appearance. In these software, you can also view the input 3D model as they all offer viewing tools like zoom, rotate, orientation, etc. Through some of these software, you can also operate a 3D printer. By feeding the G-code generated through these software to a 3D printer, you can start the 3D model printing process. A G-code carries all the necessary instructions which a 3D printer needs to create a physical 3D model. This language is primarily used in computer-aided manufacturing and 3D printing.

0 kommentar(er)

0 kommentar(er)